A Conversation With Stephen Early: Exploring ESG Compliance and Profitable Supply Chains - Part 2

Contents

Welcome to Part 2 of our three-part series, where we continue our conversation with Stephen Early, Founder of Trace SCI, on the topic of ESG compliance and profitable supply chains. If you missed our previous discussion, you can catch up on it here.

At Numeric Eight, we understand the significance of environmental, social, and governance considerations in today's business landscape. In this instalment, we explore the challenges and best practices related to traceability, transparency, and the incorporation of ESG principles into supply chains.

Traceability is widely recognised as crucial for ensuring ethical practices within supply chains. How can businesses achieve greater traceability and transparency in their supply chains? Can you provide any specific examples?

SE: To achieve greater traceability and transparency in their supply chains, businesses can take several steps. One effective approach is to implement a self-assessment questionnaire (SAQ) that is shared with suppliers.

An excellent starting point is a simple SAQ,

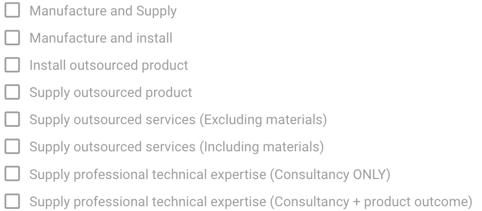

What best describes your role in supplying our company:

Alternatively:

Does your company manufacture or outsource the product supplied to our company?

This will give you an immediate position and the opportunity to identify what product you have volume to explore a direct source project and the benefits across quality/margin cash conversion cycle improvement, discount for early settlement.

More in depth questionnaires help gather crucial information about their practices and ensure they meet the required standards. Additionally, businesses should establish policies, a code of conduct, and terms of engagement that include specific requirements such as supplier accreditation in corporate social responsibility (CSR). Unannounced audits and pre-shipment inspections can also be included as prerequisites to payment, further ensuring compliance. If refused and your terms are reasonable: walk away, you saved yourself a lot of money & pain!

Let me share a success story that illustrates how an organisation tackled this challenge. There was a retailer focused on purchasing from trading companies that met their supply chain needs. They developed a small Sourcing department that recognised the importance of traceability and transparency. They conducted an assessment of their product range, mapped the volumes and buying cadence, and identified five out of seventeen product categories as a starting point for improvement.

The Sourcing Dept then engaged with three direct-from-factory suppliers for each product category, clearly explaining the parameters, including quality and workmanship, in their brief. They also provided bulk production trims and labels for blind comparison with the original products. After a month, they returned to the factories to collect the samples and receive pricing.

The Sourcing Dept presented these samples alongside the original samples to the retailers buyers. Surprisingly, 70% of the new factory counter samples were selected by the buyers. Not only were these styles of higher quality than the originals, but they also varied between 17% and 40% lower in FOB (Free on Board) USD$ than the current sources with better trading terms.

When the existing suppliers were informed about the new status quo and alternative sources, they made the choice to drop their prices by 10-15% to remain competitive. Within four years, 45% of all production across the seventeen product categories were sourced directly from factories across 4 countries instead of one.

The savings achieved from just one product category alone covered the Sourcing Dept’s overhead costs three times over on an annual basis. Even after ten years, this price and quality combination cannot be matched. In addition to cost savings, the organisation experienced improved quality consistency and reliability of delivery.

To further enhance traceability, fabric testing was introduced by converging fabric base sources. This led to consistent quality across product categories and allowed for quality confirmation before release to factories. The mills supplying the fabric became more diligent in delivering the desired qualities, and the factories benefited from combined buying power and reduced production time due to fewer fabric issues.

By prioritising traceability and transparency, this organisation transformed compliance into a profit centre, achieving significant cost savings, higher quality, and improved supply chain performance.

This Traceability and Transparency enabled the Retailer to meet independent reporting standards carried out by Baptist World Aid.

Integrating ESG principles into business operations can present unique challenges. What are some of the key hurdles that companies commonly face when incorporating ESG practices, and how can these challenges be effectively addressed?

SE: When it comes to integrating ESG (Environmental, Social, and Governance) principles into business operations, companies often face common challenges. One major hurdle is the presence of silos of activity that serve no long-term purpose. For example, companies may engage in supply chain mapping without gathering CSR accreditation or try to reduce costs by buying cheaper photocopy paper, which leads to increased paper jams and waste. These fragmented actions yield no sustainable benefits.

To effectively address these challenges, it is crucial for companies to create a Business Plan that leaders agree to adhere to. This Business Plan serves as a guiding document that outlines the company's commitment to incorporating ESG practices. It provides a roadmap for implementing these practices in a holistic and coordinated manner. By following the established plan, companies can avoid wasteful silos of action, save money and resources, and achieve sustainable benefits.

By addressing the challenges through a comprehensive Business Plan, companies can successfully integrate ESG principles into their operations and make meaningful progress towards their sustainability goals.

Beyond meeting regulatory compliance and social & ethical accountability, what are some of the key benefits that businesses can derive from integrating ESG principles into their supply chain? How does prioritising ESG contribute to the overall improvement and resilience of the supply chain?

SE: When businesses prioritise Environmental, Social, and Governance (ESG) principles in their supply chain, they can derive several key benefits beyond regulatory compliance and social and ethical accountability. Integrating ESG principles contributes to the overall improvement and resilience of the supply chain in the following ways:

- Improved quality: By prioritising ESG, businesses can establish direct communication and relationships with the source of their supply. This direct engagement enables better control and understanding of the production process, leading to improved product quality.

- Better pricing: When businesses have a clear understanding of their supply chain and work directly with suppliers, they can negotiate better pricing terms. By eliminating middlemen and intermediaries, companies can achieve cost savings and optimise their procurement processes.

- Enhanced traceability and transparency: ESG integration promotes greater traceability and transparency in the supply chain. This visibility allows businesses to track and monitor the origin of materials, ensuring ethical practices and compliance with social and environmental standards.

- Divergence of Supply Chain, reduces geographical and lower Tier supplier overlap risk.

In essence, prioritising ESG principles in the supply chain is like tuning a car. It requires a consistent, incremental process that involves direct engagement with suppliers and addressing ESG considerations holistically. Just as athletes require a balanced diet and consistent training to become long-term champions, businesses need the consistent implementation of ESG principles to drive sustainable improvements and long-term success in their supply chains.

Stephen, once again, I extend my gratitude for your valuable insights into the world of ESG compliance and supply chains. Our conversation has shed light on the importance of traceability, transparency, and the benefits of prioritising ESG principles. Stay tuned for Part 3, where we will delve into the critical social and ethical challenges in supply chains and discuss strategies for mitigating risks and promoting responsible practices.

Author Bio

Andy Rootes is a Director of Numeric Eight and is responsible for growing both Numeric Eight’s client base and developing strategic business partnerships.

Before joining Numeric Eight, Andy had many years’ experience of managing sales and partner/reseller organisations in the software technology sector in the UK, Australia, NZ and more recently across the Asia Pacific Region. He is an avid networker, focused on excellent outcomes for clients and partners alike.

About Trace Supply Chain Intelligence / Stephen Early

With a focus on turning compliance into a profit centre rather than a cost centre, Trace SCI offers supply chain intelligence that provides traceability, transparency of suppliers, and establishes direct-to-source relationships to achieve significant savings. By going beyond compliance, Trace SCI helps businesses meet short-term obligations like the Modern Slavery Act 2018 and achieve long-term Environmental Social Governance (ESG) and Corporate Social Responsibility (CSR) outcomes.

Trace SCI works with companies to assess their supply chain diversification potential and provide legacy frameworks related to risk and supply chain diversification, in conjunction with ongoing product quality and supplier performance.

Connect with Stephen on LinkedIn.